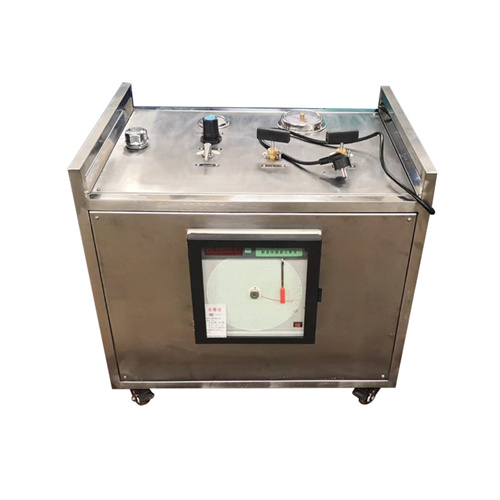

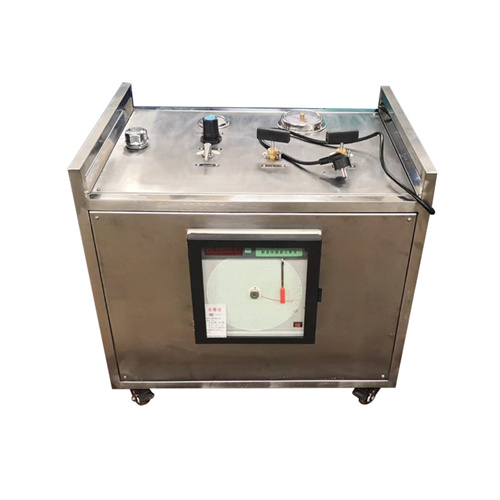

High pressure manifold test pump

Equipment introduction

High pressure manifold test pump performs pressure test for petroleum and petrochemical manifold, drilling platform liquid circulation manifold, throttling, well killing manifold and cementing manifold. Hydraulic pressure test generally requires strength and tightness test. This equipment is a gas drive pressure test system, which uses compressed air to drive, outputs high pressure liquid to provide high pressure source for pressure test, and adopts manual control. Equipped with pressure recorder or disc recorder.

Scope of application

It is used for liquid pressure test and detection of drilling fluid circulation manifold, throttling, killing manifold and other high-pressure manifold, blowout preventer, valve, pipeline, boiler and other pressure vessels in petrochemical engineering. (Pump can be used as pressure source in BOP control system)

System composition

The system consists of low pressure test pump, high pressure test pump, pneumatic diplet, high pressure stop valve, pipeline, pressure gauge, high pressure stop valve, pressure recorder, cabinet and so on

Main technical parameters

Test pressure: 0-160MPa

Pressure test medium: clean water, emulsion, ethylene glycol, etc

Drive mode: compressed air

Driving pressure: 5-8bar

Configuration of pressure test pump: high pressure pump (200:1)

Test station: 1 station

Pressure acquisition: Pressure gauge + pressure recorder (equipped with lithium battery)

Control mode: Manual

Equipment form: integrated stainless steel frame structure

关注公众号了解更多

关注公众号了解更多

Copyright © gltcn.com | GLTCN